|

What Is Pulsed Magnetic Welding? PMW is a technique for creating solid-state welds in microseconds by accelerating of one electrically conductive metal surface against another metal surface. Is it new? No, the first PMW done in America was in 1967 on a 6 kJ MAGNEFORM® machine by Douglas Nuclear.

How does it work? An intense magnetic field is created through a discharge of electrical current into a coil. An eddy current is created in the conductive work piece. The current creates a magnetic pressure that puts the work piece to be welded in motion at speeds greater than 300M/Sec.

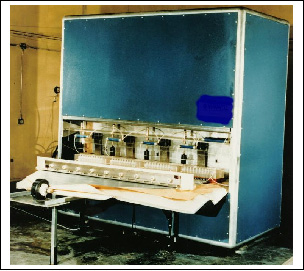

Can you describe an application? The process has been used for several applications. Two are described below. Sealing of Aluminum Pressure Vessel The requirement was to create a hermetically sealed pressure vessel using both mild steel and aluminum closures. The diameter was 2 inches [5cm]. The body was 6061 TO, and the closures 6061 T6 aluminum and 1010 steel. The welding was performed on the machine pictured above.

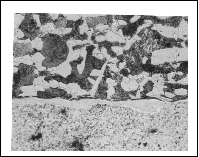

Photomicrograph below show welded interface between closure and vessel body. Peel test shows the same part.

Welding

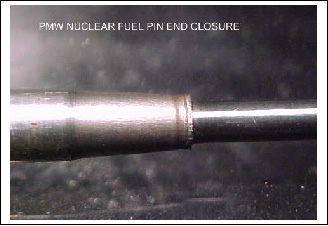

Nuclear Fuel Pins

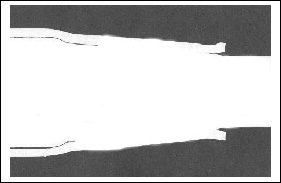

Various combinations of materials were welded including 316 Stainless Steel, Inconel 706, PE 16, and RA 330. Diameter of the outer tube was 0.230 inches [5.84 mm]. A mild steel driver was used on the outside of the tube. Below is a photomicrograph of an un-etched section of a welded fuel pin. Follow the tube from the left till it disappears. The solid section is welded.

The following electron photomicrograph shows the weld interface at x1000 magnification.

Fuel Pin Welders Two types of machines were designed and manufactures for pin welding.

Fuel Pin Welders

The circular section to the right is to accommodate a glove box in which welding takes place. What are the advantages of Magneform PMW? Advantages:

7.

Most Magneform® equipment used for welding can also be used for

forming or mechanical joining.

What

are the disadvantages? Where

are Magneform® products manufactured? All Magneform® products

have been designed and built in San Diego California, USA since 1961.

We have a full applications laboratory to serve you. |

||||||||||||||||